By Juan Cabrera-Garcia and Matt Ernst

The goal of controlled environment agriculture (CEA) is to provide an adequate environment — support, light, temperature, humidity, carbon dioxide (CO2), water and nutrients — to optimize crop growth. Crops cultivated in protected environments, such as greenhouses or indoor farms, benefit from supplemental lighting. The selection of appropriate supplemental lighting can be daunting because of the many types of grow lights available, each offering benefits for different production situations. This guide describes major types of grow lights and key considerations for selecting and using them within hydroponic systems (Figure 1).

Know your system

The selection of grow lights depends on the CEA system and farm situation. If you are planning a CEA facility, you might be considering either a traditional greenhouse, which uses sunlight and adds supplemental light when needed, or a full indoor production system, where all lighting is supplemented. If you are adapting an existing system, you might be wanting to update your greenhouse lighting, to switch from buying seedlings to starting your own in a high tunnel, or to make any other type of change that would affect your lighting system.

The amount of heat a lighting system generates and the space it occupies are important to consider. These considerations are especially crucial for “stacked” or vertical growing systems in which vertical clearance is limited and the plants are closer to the light source. In that scenario, high-pressure sodium (HPS) lamps would not be an option because their radiant heat could burn the plants, and they are too bulky for the limited space available. LED lights and fluorescent lamps, which can both be close to plants without burning them, would be an option, but these lights will also provide some heat to the plants on the shelf above them. Some LED lights allow you to separate the driver and power supply from the light fixture to balance heat dissipation. Other LED features include the ability to daisy chain multiple lights, which saves on outlet space, or connect to controllers from other brands.

Before shopping for grow lights, identify these key aspects of your system:

- Existing or new construction

- How much natural sunlight could be used

- Potential return on investment for the CEA system

- What types of lights may or may not be feasible in your system

Once you have identified the grow light possibilities for your system, you can begin comparing the light options based on four factors of lighting: light quality, uniform coverage, intensity/quantity and cost.

Light quality

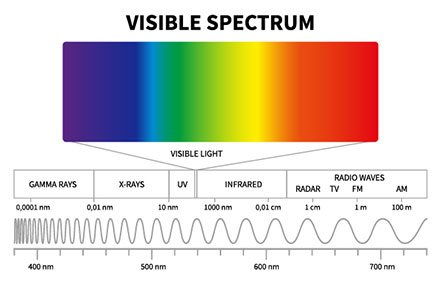

Visible light represents a portion of the radiation coming from the sun. Solar radiation is divided into wave frequencies, or wavelengths, which vary between different parts of the total light spectrum. Visible light is composed of multiple colors, with each color indicating a different wavelength (Figure 2). Plants evolved to use light ranging from ultraviolet to far-red for many physiological processes.

The ability of a plant to yield sugars through photosynthesis peaks in the wavelengths landing in the blue and red colors, those generally measuring between 400 and 700 nanometers (nm). This spectral range of radiation that is active for photosynthesis is called photosynthetically active radiation (PAR). The first step when shopping for grow lights is to check for a spectrum graph to determine if the lights emit radiation in the PAR range.

You might see other units, such as lumens and Kelvin color temperature, when comparing grow lights. Those units represent light that human eyes perceive, not the light that plants use to grow. When shopping for grow lights, focus on the PAR range. Avoid lights listing units such as lumens, lux, candelas and Kelvin color temperature.

Light color can also drive processes other than photosynthesis in plants. Radiation within the red and far-red wavelengths promotes plant growth and tissue expansion. In some long-day plants, adding roughly equal parts of red and far-red light stimulates flowering.

Blue and ultraviolet light promotes accumulation of phytonutrients, which may benefit human health; however, excessive blue light will stunt plant growth. Microgreen growers use this information to improve the nutritional quality of their produce. Some microgreen growers grow their plants under full-spectrum light for two-thirds of the crop life and finish the crop under blue and ultraviolet lights in the last few days of the growth cycle to promote phytonutrient accumulation.

Some lighting products emit light in the ultraviolet and far-red light spectrum to supplement lights that only cover the PAR spectrum. Greenhouse growers may benefit from using such supplemental lighting because greenhouse coverings have additives that block UV radiation so as to improve the longevity of the covering and may have additives that block far-red radiation so as to preserve thermal energy during the winter months.

Before shopping for grow lights, answer these questions about light quality:

- What are the light-quality requirements of the crops that I will grow?

- Do these light-quality requirements change during the plant’s life cycle?

- What light quality will I need to supplement?

- How will seasonality affect light-quality requirements?

Shopping for grow lights

- Check if the manufacturer provides a light spectrum graph. Does the fixture provide light in the PAR range and/or supplemental blue/UV and far-red range?

- Check for PPFD distribution maps, or use a quantum sensor to measure PPFD at the desired height. Does the fixture provide optimal light intensity at the intended distance from the plants?

- Check for information on how many watts the light uses per hour. How much electricity does the light use? Light manufactures provide efficiency figures in units of μmol/J with HPS light ranging from 0.9 to 1.7 μmol/J and current LEDs having values over 2.5 μmol/J. Higher numbers equal higher energy efficiency.

- Avoid buying lights if the manufacturer does not provide a spectrum graph and PPF or PPFD information.

Uniform coverage

Consult a professional installer to determine the best location of lights to provide uniform coverage.

Light intensity

The PAR does not refer to the light intensity; PAR only refers to the wavelength, or color, emitted by the light source. The intensity of light in the PAR range is measured as photosynthetic photon flux (PPF).

The PPF is a measure of how much photosynthetically active light — light in the PAR range of 400 to 700 nanometers — is being emitted each second by a light source. PPF is measured in micromoles per second (μmols/s). There are 62 quadrillion photons, or light particles, in 1 micromole of light.

The PPF is used to calculate photosynthetic photon flux density (PPFD). PPFD is measured in micromoles per square meter per second (μmols/m2/s): how much instant light reaches the plants in a given area at a set distance. Light intensity and distance from the light source impact PPFD, which tends to be higher when the light source is closer to plants. The optimal PPFD varies between plants and may vary for different plant growth stages.

Calculating the DLI for lettuce

This example shows how to calculate the time to run the lights for a crop with an optimal photosynthetic photon flux density (PPFD) of around 510 μmol/m2/s and needing 16 mols/m2/day of daily light integral (DLI) in a full indoor production system.

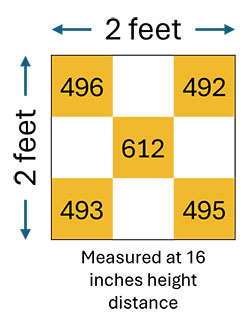

To calculate DLI, use the PPFD map that is provided by the light manufacturer or use a quantum sensor to measure PPFD in each corner and the center of the light coverage. PPFD maps will be provided for different height distances between the plants and the light source. This example will use numbers from the PPFD map shown in Step 1.

Step 1. Calculate the average PPFD value from the PPFD map provided by the manufacturer or that you measured. Use the values from each corner and the center of the PPFD map. Add the five values and divide by 5.

496 (Corner 1) + 492 (Corner 2) + 495 (Corner 3) + 493 (Corner 4) + 612 (Center) = 2,588

2,588 ÷ 5 = 517.6 μmol/m2/s average PPFD

Step 2. Calculate the hourly PPF. Multiply the average PPFD by 3,600 and divide by 1,000,000.

17.6 × 3,600 ÷ 1,000,000 = 1.86 moles/m2 per hour

Step 3. Calculate how many hours you need to run the lights to supply the needed DLI. Divide crop required DLI (16 mols/m2/day in this example) by the hourly light supplied by the light (result from Step 2).

16 DLI ÷ 1.86 = 8.6 hours

You can also download the Indoor Grow Light Calculator (XLSX) to estimate how long to keep the lights running and how much it will cost.

Lettuce, for example, needs a PPFD, or instant light intensity, between 250 and 350 micromoles per square meter per second (μmols/m2/s). Lettuce plants may still look healthy when the PPFD exceeds 350 μmols/m2/s, but providing light at that level would be a waste of energy because it would not result in a significant increase in yield or decrease in harvest time. Moreover, excessive light can cause photoinhibition, in which photosynthesis is inhibited and thus plant growth is reduced. Providing light in the wrong PPFD forgoes yield, wastes electricity and can damage the plants.

The PPFD is used to calculate daily light integral (DLI). DLI is the total amount of light in the PAR color range that a plant needs per day. DLI is presented as moles of light per square meter per day (μmols/m2/day).

The cropping system you use will affect the lighting recommendations for plants. In a greenhouse, for example, natural sunlight will provide much of the DLI. Sensors measure the light provided by the sun to estimate if additional lighting is needed, and if so, the control unit will turn on the lights until the desired DLI is reached.

In a full indoor production system, you can use the information provided by the light manufacturer to calculate how long to keep the lights on. Light manufacturers usually provide the expected PPFD levels at different heights, or you can use a quantum sensor to measure the PPFD of a light source. See the “Calculating the DLI for lettuce” example for an explanation of the calculation.

Before shopping for grow lights, answer these questions about light intensity:

- Do I understand the basics about DLI and PPFD?

- What are the DLI and PPFD requirements for the crops I am going to raise?

- Which lighting type will be best for my lighting and crop needs?

Calculate your costs

Although you do not have to pay for natural sunlight, you will have upfront costs in building a greenhouse so that plants benefit from sunlight energy. Depending on market demand, greenhouse producers may choose to supplement sunlight with grow lights that extend the growing season.

Long-term cost comparison of light sources

Use this example as a format to compare different types of lights and make decisions on which lights to purchase.

Suggested cost period: 5 years (1,825 days)

Hours light per day: 8 hours

Total light hours: 8 × 1,825 = 14,600 hours

14,600 × (Watts used per hour, from manufacturer) ÷ 1,000 = Total kilowatt-hours

Total kilowatt-hours × Price per kilowatt-hour = 5-year electricity cost

Total kilowatt-hours ÷ kilowatt-hours bulb life = Bulb replacements needed (If more than 1.0)

Bulb replacements needed × Number of bulbs × Price per bulb = 5-year bulb cost

5-year electricity cost + 5-year bulb cost = Cost of grow light operations

There are some basic cost differences between types of lights. To accurately compare lighting costs, you must consider the upfront cost to acquire the lights, the longevity of the lights, and the energy-use efficiency. High-pressure sodium lights are going to be less expensive for the number of light fixtures and have a wider coverage area. However, although HPS systems require the lowest initial investment, they are the least energy-efficient option and have the shortest life, resulting in the highest long-term cost. Conversely, LED lights have a high initial investment, but they last significantly longer and are the most energy efficient of the light options, resulting in the lowest long-term cost. Fluorescent lamps are more efficient than HPS and are between HPS and LED in terms of initial investment, energy-use efficiency and lifespan.

There is a direct relationship between energy efficiency and the initial capital investment in lighting systems. LED systems usually require the higher initial investment but are the most energy efficient and have a longer useful life. LED lights can also be customized to deliver specific light recipes.

Because each situation will likely be different, you need to calculate the initial investment for the grow lights and the cost to operate and maintain the lights, that is, your fixed and variable costs, respectively. You can estimate these costs using assumptions based on information provided by grow light manufacturers.

Calculating daily lighting energy

This example shows how to calculate lighting energy usage. It is based on the “Calculating the DLI for lettuce” example.

Remember these conversion factors:

- 1 watt-hour = 3,600 J (Joules)

- 1 mol = 1,000,000 μmol (micromoles)

In the “Calculating the DLI for lettuce” example, the lights need to run for 8.6 hours to provide a daily light integral (DLI) of 16 mol/m2/day. After looking at the light spec sheet, you notice the lights have an efficiency of 2.5 μmol/J and a photosynthetic photon flux (PPF) value of 850 μmol/s.

Step 1. Calculate the amount of light that the lamps will emit while they are on. First, multiply the light’s PPF by the run time in seconds (there are 3,600 seconds in one hour).

Hour-to-second conversion:

8.6 hours × 3,600 = 30,960 seconds

Total light output (PPF × run time in seconds):

850 μmol/s × 30,960 s = 26,316,000 μmol

Step 2. Divide the amount of light emitted in the run time (μmol from Step 1) by the energy efficiency rating of the LED light.

26,316,000 μmol ÷ 2.5 μmol/J = 10,526,400 J

Step 3. Calculate the amount of electrical power used by the light during the run time. Divide the energy in Joules by the number of Joules in 1 watt-hour.

10,526,400 J ÷ 3,600 = 2,924 watt-hours or 2.92 kWh per day

Source : missouri.edu