By Virginia A. Ishler

Production perspective:

It is that time of year when heat and humidity impact dry matter intake and cow comfort. Many Pennsylvania dairy herds house their cows in tie-stall or stanchion barns that are unable to incorporate heat abatement strategies as easily as in free-stall housing. Herds with antiquated facilities must rely on feeding management strategies to help mitigate heat stress. However, there are limitations on how much can be done to help cows maintain intake.

Ventilation and air movement during times of extreme heat is imperative to keep cows comfortable and willing to eat. Component feeding, which is focused on the individual cow, is still very common in tie-stall/stanchion barns. Feeding by volume versus weight is prevalent and can be challenging. Controlling high feed costs may result in ingredient changes for grain mixtures from load to load. If forage inventories are limited, green chop may be fed until ensiled feeds have fermented properly. These scenarios can affect the weight of feeds delivered when using the volume approach. There are methods to ensure cows are fed the correct amount.

Many producers think in bushels compared to an actual weight. This approach can be used when feeding but it will require an occasional measurement to ensure the assumed weight matches the bushel. For example, the pounds per bushel will vary significantly depending on a grain mixture's physical form. A general guideline is a coarse textured grain mix weighs 44 lbs./bu. compared to 33 lbs./bu. for a meal, and 50 lbs./bu. for a pellet. A grain mix containing a lot of small grains or byproducts (e.g., midds or soyhulls) will typically weigh less per unit of volume than mixtures containing a lot of corn. Accounting for these differences can avoid over- or under-feeding grain. Having a regular "calibration" plan in place is recommended. Ideally this should be done on every new delivery of concentrate mixes.

One of the biggest mistakes in feeding is with green chop. Because the volume amount seems so large, it is assumed that cows are receiving adequate forage intake. Green chop forage weighs approximately 20 lbs./bu. compared to silage that ranges from 15 to 30 lbs./bu. depending on the dry matter. With dry hay, a slice can have different weights depending on if it is alfalfa, grass, or a mixture. Occasionally weighing a slice or a bale is helpful in ensuring cows are getting the recommended amounts. This is an important fundamental principle, especially during the summer months. Feeding the correct proportions of forage and concentrate is necessary so animal performance and health are not compromised.

Feeding sequence in component fed herds is another critical management practice. The goal is to mimic a TMR system by avoiding extremes in rumen pH. A common example is slug feeding grain, which can lower rumen pH and depending on how long it stays low, has implications for acidosis and milk fat depression. Some guidelines are feeding forage before grain. Ideally, feed hay first however if hay is not available, then silage. Energy feeds such as high moisture corn should be fed before a high protein feed or supplement. Energy feeds typically take longer to be broken down in the rumen. Feed protein and mineral containing items reasonably close to a feeding of items low in these nutrients, such as corn silage. Increasing feeding frequency of grains and forages can encourage intake during times of heat stress.

Component feeding is more labor intensive compared to other systems. The advantage is feeding the individual cows versus a group, The summer can be challenging depending on the facilities and available labor. However, with milk prices looking favorable toward the end of the year, minor feeding management adjustments might be enough to keep cows eating and chilling.

Economic perspective:

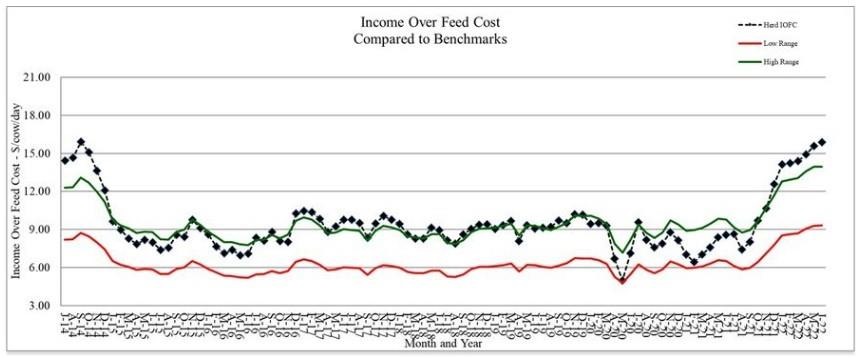

Monitoring must include an economic component to determine if a management strategy is working or not. For lactating cows, income over feed cost is a good way to check that feed costs are in line for the level of milk production. Starting with July 2014’s milk price, income over feed cost was calculated using average intake and production for the last six years from the Penn State dairy herd. The ration contained 63% forage consisting of corn silage, haylage, and hay. The concentrate portion included corn grain, candy meal, sugar, canola meal, roasted soybeans, Optigen, and a mineral vitamin mix. All market prices were used.

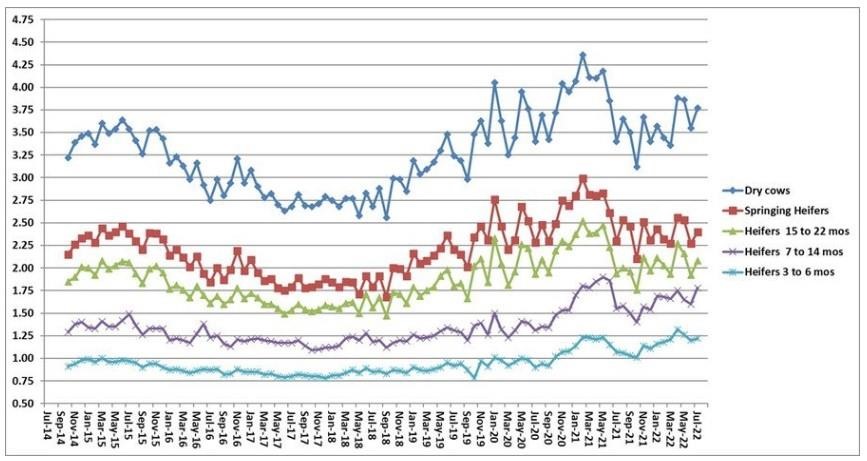

Also included are the feed costs for dry cows, springing heifers, pregnant heifers, and growing heifers. The rations reflect what has been fed to these animal groups at the Penn State dairy herd. All market prices were used.

Income over feed cost using standardized rations and production data from the Penn State dairy herd.

Note: June's Penn State milk price: $28.02/cwt; feed cost/cow: $7.39; average milk production: 83 lbs.

Feed cost/non-lactating animal/day.

Source : psu.edu