By Christian Nansen

The western tarnished plant bug (or lygus bug) and different species of spider mites are major arthropod pests in California strawberries. While predatory mite releases are very popular for controlling spider mites in both organic and conventional fields, a significant amount of chemical pesticides are used for arthropod pest management in conventional fields. Nearly 280,000 pounds of active ingredient of at least 30 chemical and botanical pesticides were used in 2016 in California strawberries (USDA-NASS, 2016; CDPR, 2017) and malathion, bifenazate, naled, acequinocyl, and fenpropathrin were the most common of about 79,000 pounds of chemical pesticides. A uniform and thorough coverage of pesticide sprays is essential for effective pest management and also for reducing excessive pesticide use that could lead to resistance and environmental health issues (Shi et al., 2013). Evaluation of pesticide spray applications and their performance will help improve current pest management strategies in strawberry as they did in other crops (Nansen et al., 2011; Nansen et al., 2015).

Several factors such as the tractor speed, spray nozzles, spray volume, boom height, adjuvants, pressure, canopy characters, micro and macroclimatic conditions influence the spray coverage. A better understanding of these factors will help improve the pesticide use and efficacy, optimize the cost, and reduce pesticide drift and other associated risks (Nansen and Ridsdill-Smith, 2013).

A study was conducted during 2016 and 2017 to evaluate multiple spray configurations under varying weather conditions where more than 4000 data points were collected. Data for only two spray configurations, using Albuz ATR 80 Lilac and Albuz ATR 80 Green nozzles, are shown here.

Collecting the spray cards for evaluating the spray coverage (above).

Water-sensible spray card in the strawberry canopy (above) and determining the spray coverage with the help of SnapCard app (below).

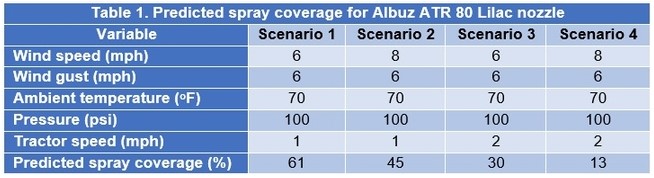

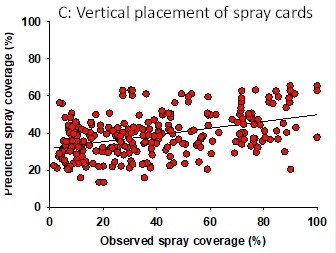

Configuration 1: Albuz ATR 80 Lilac nozzles were used in 144 experimental applications delivering 32-80 gallons of spray volume per acre. Water-sensitive spray cards (TeeJet, Wheaton, IL) were clipped to the petioles of strawberry leaves in horizontal and vertical orientation (1 card per application for each orientation). They were placed in the strawberry canopy prior to spray applications and the coverage was determined based on the pattern on the cards using the SnapCard smartphone application. Data suggested that spray volume does not always translate into a good spray coverage (Fig. 1). There was a wide variation in the coverage that ranged from 0-55% at 33 gpa and 5-80% at 80 gpa suggesting the influence of other factors. Taking the operational and weather conditions into account, a multiple linear regression analysis was conducted to measure the relationship between predicted and observed spray coverage which appeared to have a linear correlation (Adjusted R2=0.27; F+52.6; P < 0.001) (Fig. 2). Wind speed, wind gust, ambient temperature, pressure, and tractor speed were used as explanatory variables in this analysis. Based on this regression model, four possible scenarios were developed with predicted spray coverage values (Table 1). A 2 mph increase in the wind speed from 6 mph to 8 mph could reduce the spray coverage from 61 to 45% when the tractor runs at 1 mph or from 30 to 13% when the tractor runs at 2 mph.

Fig. 1. Spray coverage related to the volume using the Albuz ATR 80 Lilac nozzle.

Fig. 2. Modeling spray coverage under different conditions using the Albuz ATR 80 Lilac nozzle.

Configuration 2: Albuz ATR 80 Green nozzles were used in 276 experimental applications delivering 180-440 gallons of volume per acre. Since the droplet size from the Green nozzle is much larger than that from the Lilac nozzle, a better coverage is expected with the presumption of lesser sensitivity to environmental and operating conditions. However, data from the spray cards indicated a poor relationship between the spray volume and coverage under this configuration as well (Fig. 3). For example, both 200 and 350 gpa had a similar spray coverage. Multiple linear regression analysis, using strawberry canopy characteristics (plant height and width, dry weight, and canopy coverage), operating and weather conditions as explanatory variables, showed a significant linear correlation (Adjusted R2=0.45; F=199.5; P < 0.001) between observed and predicted spray coverages (Fig. 4). A prediction model under this configuration showed nearly 20% decline in spray coverage when the tractor speed increased from 1 to 2 mph (Table 2). Wind speed appeared to have a minimal impact, probably due to the droplet size.

Fig. 3. Spray coverage related to the volume using the Albuz ATR 80 Green nozzle.

Fig. 4. Modeling spray coverage under different conditions using the Albuz ATR 80 Lilac nozzle.

This study demonstrates the importance of weather and operating conditions on spray coverage. Additional data will be collected in 2018 to expand our understanding of the factors that influence spray coverage. These studies will be useful to determine appropriate operating conditions such as the spray volume, tractor speed, and types of nozzles and identify weather conditions that are ideal to achieve good coverage. A free smartphone application is under development for the growers and PCAs to input weather and operating conditions to predict the spray coverage. This information will ultimately improve the pest control efficacy and contribute to sustainable pest management practices.

Acknowledgments: We thank the financial support of the California Strawberry Commission and the collaboration of several growers. We also thank the technical assistance of Daniel Olivier, Marianna Castiaux, and Ariel Zajdband, California Strawberry Commission and Robert Starnes, Jessie Liu, Laurie Casebier, Haleh Khodaverdi, and Isaac Corral, UC Davis.