According to U.S. Department of Agriculture National Agricultural Statistics Service, over the last decade hay production has decreased 11 percent while at the same time, hay prices have concurrently increased 77 percent.

"With the markets where they are, livestock producers cannot afford to let any hay go to waste," said Taylor Grussing, SDSU Extension Cow/Calf Field Specialist. "Depending on which form hay bales are delivered, the amount of waste will vary."

Selecting the right design for their hay feeder can help South Dakota livestock producers cut down on waste according to research conducted at the University of Missouri Agriculture Experiment Station.

Researchers analyzed the effect of bale feeder design on hay waste.

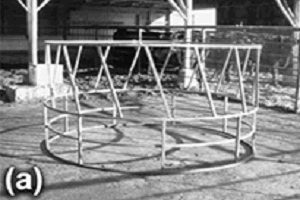

The three bale feeders evaluated included an open bale feeder, a tapered bale feeder with sheeting on lower section, and a cone bale feeder with sheeting on the lower and upper sections.

Two different types of hay: alfalfa haylage bales, and fescue hay bales, were also utilized to evaluate interaction of bale feeders and forage.

All bales were placed into bale feeders horizontally and cows utilized in the study were accustomed to bale feeders and forage types prior to study initiation.

Bale feeder study results

Researchers found that for fescue hay bales, cone feeders resulted in the least waste with only about 8.9 percent; tapered feeders showed 13.6 percent waste, and open feeders resulted in the most waste at 19.2 percent.

"These results agreed with previous research by other authors where cone bale feeders reduced waste of dry grass bales. However, alfalfa haylage waste was not affected by feeder design," said Grussing.

Stocking density impacts waste

The study also showed that stocking density and size of bales can play a key role in forage waste.

"Greater stocking density will increase competition around bale feeders and reduce the time cows spend entering and exiting the feeder, potentially decreasing waste," Grussing said.

She added that bale size may have been one reason there was less waste with alfalfa haylage than fescue hay.

"The smaller-sized alfalfa haylage bales, provided cows more feeding space in bale feeders, and reduced the entrance/exit frequency and waste opportunities," Grussing said.

Overall, cone bale feeders resulted in 35 percent less waste than tapered bale feeders. Tapered bale feeders with lower section sheeting resulted in 29 percent less waste compared to open bale feeders with no lower section sheeting.

Cow/calf producers can prepare for winter feeding by taking a look at the type of bale feeders on hand.

Do bale feeders have sheeting on the lower section? If not, can some kind of sheeting (metal or plastic) be added to help decrease waste this winter?

Are enough bale feeders available for the cowherd size or do more need to be purchased?

"Regardless of its design, feeding in any type of bale feeder is better than feeding directly on the ground which greatly increases waste and thus pounds of feed required per day to meet nutritional requirements," Grussing said. "Expenses can add up quickly with forage waste and extra pounds of hay are needed to meet requirements."

Grussing shared the example. Assuming the forage is $80 per ton; as little as 1 pound of waste per cow per day accumulated over a four-month winter feeding period, can add at a minimum an extra $5 to the cow's winter feed bill.

"And this expense will continue to increase with tapered and open bale feeders as more waste is expected," Grussing said.

Click here to see more...