By Mathew M. Haan

A look at feeding management in Pennsylvania robot herds.

A properly balanced ration and good feed management are important to achieving production goals and maintaining cow health on dairy farms. On robotic milking dairy farms nutrition and feed management take on another important role, motivating cows to the robot. In robotic milking systems, cows receive a partial mixed ration (PMR) at the feed bunk and additional feed from the robot during milking.

If a cow meets all of her nutritional needs from the PMR there is no incentive for her to go to the robot. In addition to balancing the nutritional needs of the cow, the robot feed must be palatable and of consistent quality. The robot feed must also be something that the cow can consume quickly (2 or 3 times per day for about 7 minutes per feeding), and it must be affordable.

Feed Costs

It has been reported that feed costs on dairy farms using robotic milking systems is higher than in parlor or tie-stall systems. The cost of feed dispensed by the robot is often given as the reason for higher cost in robotic systems. Most herds feed a single pelleted feed through the robot. However, some feed a ground meal or multiple feeds (for example, all cows receive a pelleted feed and high producing cows receive roasted soybeans in addition to the pellet). The amount of feed dispensed is based on days in milk or milk production of the cow, allowing the manager or nutritionist to tailor the ration to each cow’s individual needs.

In a sample of 8 Pennsylvania dairy farms using robotic milking systems, cows received an average of 9.7 pounds of feed per cow per day from the robotic milker. Robot feed cost an average of $344 per ton on these farms. Of these 8 farms, one used a guided flow system (averaging 7 pounds of feed per cow per day from the robot) with the remainder being free flow systems. Most farms fed a pelleted feed through the robot with one farm feeding a ground meal, this farm had the lowest cost robot feed ($270 per ton).

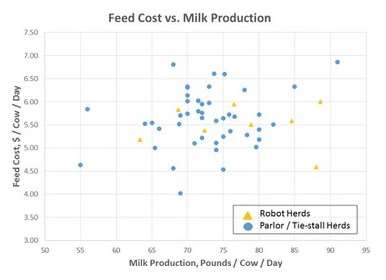

Figure 1 shows feed costs per cow per day versus milk production on these 8 farms (yellow triangles) compared to 46 Pennsylvania dairy farms milking in a parlor or tie-stall facility (blue circles). Data from the 46 non-robotic milking farms came from farms participating in the Penn State Extension Cash Flow Planning program in spring of 2017. To standardize the cost of home-raised feed costs across farms, all home-raised feeds were assigned a market price value calculated monthly by Penn State.

Feed cost per cow per day averaged $5.50 ($4.59 to $6.00) on the robotic milking farms and $5.64 ($4.02 to $6.86) on the non-robotic milking farms. Milk production per cow averaged 77.6 pounds per day (63.3 to 88.6) on robotic farms and 72.7 pounds per day (55.0 to 91.0) on the non-robotic milking farms.

Robot Feed Characteristics

Five of the robotic milking herds provided the formulation for the pellet fed through the robotic milker. Pellets contained 4 to 21 ingredients, and wheat midds or corn grain were the major ingredients. Wheat midds were included in 4 of the 5 pellets, at a rate of 10 to 60% of the pellet. Corn was also included in 4 of the 5 pellets, at a rate of 27 to 50% of the pellet. All pellets contained molasses or some type of flavoring to improve palatability of the pellet.

Source: psu.edu