By Sara Bauder

Fall is a very busy time on most grain farms in South Dakota. In the hustle and bustle of running the combine, hauling grain, and storing or selling a crop, it is easy to forget the importance of safety. According to the US Center for Disease Control (CDC), agriculture ranks among the most hazardous industries. This does not come by surprise to most ag producers. However, the potential for accidents due to inexperience or complacency (after many years of farming) is real.

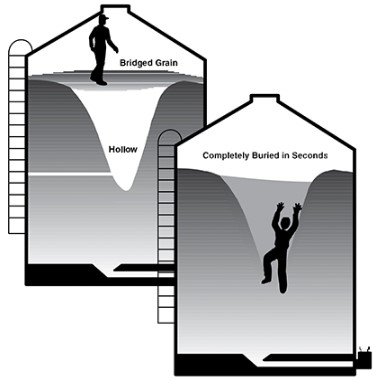

Every year, farmers across the US are injured or killed in grain handling related accidents. In 2017, 54 cases of agricultural ‘confined space-related’ accidents were reported, with 31 fatalities in total. Of these incidents, grain entrapment was the leading cause with 23 cases reported, resulting in 12 fatalities. (Figure 1). According to a recent publication, South Dakota had one reported confined space incident in 2017, but 49 cases documented since 1962 (n=1989) (Cheng and Field, 2018). It takes only 3-4 seconds to be rendered helpless in flowing grain, and the average person can be buried in about 20 seconds (Hellevang, 2013).

Figure 1. Distribution of all 2017 agricultural confined space-related cases by type of incident, N = 54.

Suffocation, entanglement, crushing, explosions, and carbon dioxide poisoning are some of the biggest risk factors when handling grain. What steps can be taken to keep yourself, your family, or your employees from becoming a statistic? Education and precaution should come first; farm safety should be a daily habit for all involved in the operation.

Safety Tools to Install

- Install exit ladders inside of bins. Paint them with bright colors to make them easy to see in a dark, dusty environment.

- Hang a ‘life-line’ from the center of the roof to provide an additional escape route (Figure 2). Life-lines are available for commercial purpose or you can create one by attaching a rope with knots or a sturdy hanging ladder from the peak of the inside of a bin.

- Lock out procedures should be in place on grain moving equipment so that when entering a bin, no one else can turn on augers or other equipment. This can be as simple as a padlock.

- Use safety decals on storage facilities as a reminder of the dangers of flowing grains.

- Be sure all exterior ladders are stable and caged (especially if longer than 20’) to avoid falls upon entrance.

Figure 2. Always stop machinery before entering bins. Use a life line if you must enter a grain bin! If improperly used, a life line can cause injury to the spinal column. Install a permanent life line in each bin.

Operating Procedures

- Never allow children to play or work in the area of flowing grain no matter what the circumstance.

- Before entering a bin, shut off power to all grain moving equipment and lock it out to prevent others from starting equipment while you’re inside.

- Never enter a bin/wagon/truck when grain is flowing.

- Always wear a safety harness when entering bins.

- Upon entering a bin, stay near the outer wall and keep walking if grain starts to move.

- If grain is crusted, take extra caution (Figure 3). Break up crust from outside the bin with a long rod or stick before entering, taking care to avoid electrical lines.

- If grain is in a steep pile, use a long pole to dislodge- not a shovel.

- Work in groups. Grain handling can be very dangerous and having 2-3 people present at all times can significantly impact the safety of workers, especially in the event of an emergency.

- Wear an appropriate filtered mask when working in bins, especially when cleaning.

Figure 3. Hollows may develop under crusted grain when grain is removed from the bin; this forms a bridge of grain. When the bridge collapses under your weight, you can be buried in seconds.

Click here to see more...