By Doug Mayo

There is no question that cattle ranchers will have to make some challenging decisions to reduce expenses in the face of a deflated cattle market. Chris Prevatt, UF/IFAS Regional Livestock Economist provided the chart above, which tracks the US weekly average for 550 pound steer calves for the past eight years. While prices have improved a little since October, they are still hovering around breakeven. Still, $1.30/lb is less than half of the income from 2014 and 2015.

With reduced income from weaned calves and cull cattle, cow-calf producers are going to have to make some tough decisions to remain profitable. Back in 2009, a brain-trust at the University of Georgia developed a really nice publication called Cutting Costs, Not Corners: Managing Cattle in Tough Times. While the prices and budgets used in this publication are outdated, the key concepts are still right on target. The main focus of this document is still worth sharing; simply cutting corners is not the best answer long-term.

Cutting costs allow producers to survive during trying times, and also teaches valuable lessons that may actually increase profits in future years. Cutting corners, on the other hand, may save some money in the short-run, but ultimately will have very detrimental effects. Stewart, et al.

Ultimately, you don’t want to sacrifice herd performance and pasture productivity in exchange for cost savings, if it will result in serious long-term impacts. When the market rebounds, you want to be able to take full advantage of the resources you have invested years developing.

Where to Start?

The place to begin is by analyzing the previous year’s production and financial records. Use the data from your 2016 Schedule F Form that will be used to file your federal taxes. How much did you spend in 2016 on the major categories? After crunching the numbers for your individual operation, you may come up with a ranking of annual costs similar to Figure 2 below.

The categories that stand out are the three related to providing the daily nutrition for the herd. Pasture, hay, and feed add up to almost 70% of the expenses for cow-calf operations. herd health and mineral, the purple bar, are a much smaller percentage of the overall operating budget. Saving money by cutting corners on vaccination, dewormer and mineral could reduce your expenses, but the overall impact to the total budget will be small. Yet cutting these expenses could have a devastating impact to the health and productivity of the herd. Instead, you will have much more impact reducing the three nutrition categories than any of the others.

The challenge is to reduce the cost of nutrition without negatively affecting reproduction and other phases of cattle performance. The University of Georgia publication, mentioned above, offers a variety of cost cutting ideas, and is well worth the time to read. The following are four of their suggested management options that can have a sizable impact on reducing the expense of beef herd nutrition.

Management Options to Reduce Costs

1. Matching Calving Season to Forage Production

One area that is seldom discussed, but can have a huge impact on feed costs, is the timing of the breeding and subsequent calving seasons. More closely matching calving to the forage production calendar can have a major impact. If bulls remain with the herd year round, this is impossible to manage, but with a depressed market, now is a great time to consider adjusting the breeding season.

Figure 3 illustrates the huge difference between the nutreint requirements of dry, pregnant cows, and lactating cows with calves at their side. Peak nutrient requirements for the year take place 30-90 days after calving. Yet over much of the Southeast, this peak nutritional need takes place in the fall and early winter, when pastures are at their worst. One simply method for reducing hay and supplemental feed costs is to shift the breeding season back a month or two. Instead of beginning the breeding season in January for October calving, turn the bulls in with the herd in March for December calving. This shift in calving season fits in much better with winter annual and permanent pasture forage production.

There is a key reason so many operations in the Southeast calve in the fall. Typically spring and early summer calf prices are the highest for the year, so delaying calving can impact income the sale of weaned calves. You have to end up with more savings than income loss, so this decision should not be made lightly. But even with a December to February calving season, weaned calves can still be sold in August ahead of typical fall price drops. Totally matching the growth curve of bahiagrass pastures with the breeding season is probably not the best option, because then calves would be marketed at the same time as the rest of the country, and at the lowest levels for the year. If you are currently calving year round, or in the fall, this is one option for reducing feed costs.

2. Reduce Herd Size

Another option to reduce feed costs is to simply feed fewer cows. With lower stocking rates, pastures can provide more forage per acre for the cows that remain. This herd reduction would have to be substantial enough to make a real difference, not just a 5 to 10%. Reducing the herd 25-50% will reduce the pressure on pastures as well as hay fields. If pastures were stocked to the maximum limit during high cattle prices, it may be time to sell of some off the poorer performing, older cattle to reduce costs. As the market improves, additional cattle could be purchased to rebuild the herd again later on. There is an obvious problem, however; fewer cows results in fewer calves to sell, and even lower income. Fixed costs per cow, such as hay equipment, tractors, and trailers, will actually increase because there will be fewer cows to share these costs. If you are operating at or near breakeven at this point, however, it is better to keep fewer cows and still provide adequate nutrition than to just feed less to the current herd just to save money. There are immediate consequences for inadequate nutrition. Reproduction is the last system supplied energy when energy is in short supply, so cows will remain open longer in the breeding season, until pastures grow enough to make up the short fall. The cows immune system can also be depressed, if energy needs are not met. In the end it is better to feed and graze fewer cows than to just cut back to save money.

3. Targeted Pasture Fertilization

One expense that always seems to be a focus is fertilizer costs. Since pasture fertilizers are most commonly ordered all at one time each spring, this is normally one of the largest single bills to be paid. In general, fertilizer is the largest annual expense for pastures. There are some things that can be done to reduce the fertilizer bill. Soil testing is more critical than ever to ensure that only the limiting nutrients are applied with each fertilization.

One area of pasture fertility that should not be eliminated is soil pH maintenance. In the chart to the right, the widest parts of the bars represent the pH when each nutrient is most available and useful to plants in the soil. On the very first line of the chart you can see that when the pH drops below 5.0, nitrogen is less available to the plant. In other words, at lower soil pH no matter how much fertilizer you apply, less is utilized by the plant. If there is not enough money to cover the expense of lime and fertilizer for every acre of pasture that needs it, the lime should not be skipped. Send in those soil tests and make sure the pH stays above 5.5 for optimal forage growth. If soil test results indicate lime is needed, then apply it, don’t skimp on lime.

Put your money where you will get the greatest return. Spring fertilization provides greater returns than in late summer. Nitrogen (N) is the “Gas that makes grass grow.” No other nutrient provides the yield boost that nitrogen fertilization does. It is be better to only fertilize your most productive pastures with 50 lbs.N/acre in the spring, than to fertilize double the acreage with only 25 lbs.N/acre. At 25 lbs.N/acre your weeds will grow faster than your grass. Just make sure to record which pastures were fertilized, so you can pick up the others in the years ahead.

If you decide to use the 50 lbs.N/acre rate on bahiagrass pastures, UF/IFAS recommends no potassium, and only 25 pounds of phosphorus per acre when the soil tests low for P205. (This is not the case for hay production, where these nutrients are removed from the field with every cutting.) You can also save money utilizing poultry litter as the source of this nitrogen, instead of conventional fertilizer. Just be mindful of the odor and the impact it can have with neighbor relations.

More detailed information on this subject is available in the publication Fertilizing and Liming Forage Crops. If you decide to cut out pasture fertilization all together this year, be aware the weeds will have a competitive advantage, and will eventually take over. You also will need to adjust reducer stocking rate, because unfertilized pastures are much less productive, and will take longer to recover after grazing.

4. Grazing Management

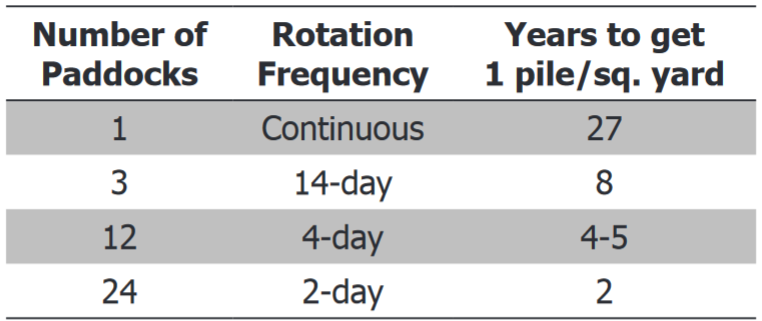

One area of ranch management that is often overlooked is grazing management. The photo above shows the difference in root growth from Bahiagrass that was never grazed, mob grazed with 21 days rest, grazed down to 50% every three days, or grazed off continuously every three days. If cattle stay in the same pastures continuously they will selectively eat the tender growth and force forage plants to shed some of their roots to survive. Eventually the grass will die out and invasive weeds and grasses, such as centipede and broomsedge will take their place. The old rule of thumb for grazing is “Take Half and Leave Half.” The idea is to graze forage down halfway and move them to a new pasture. This photo shows why that is so important. You don’t have to build an intensive grazing system with 22 paddocks and daily rotation for each herd, but you can certainly improve the efficiency of a pasture by rotating cattle more frequently.

Not only does rotational grazing benefit the health of forage plants, but it also provides better nutrient recycling through more even manure distribution. Keeping cattle from congregating in the same places each day distributes the nutrients around pastures more evenly. Unlike the situation with hay production, very little nutrients are lost in the form of weaned calves leaving the farm. With more regular rotation, nutrients added from feed and fertilizer are more evenly redistributed in manure. While moving cattle to a new paddock every two days may not be feasible in your operation, this study does demonstrate the concept well. The more often cattle rotate and graze a new paddock the more efficiently pastures can be utilized. More frequent pasture rotation does require more labor, but the benefits of more productive, and healthy forage plants, and the more efficient recycling of feed and fertilizer nutrients are worth the extra time required.

Summary

The four management options discussed in this article are just a few of the concepts worth evaluating in the publication, Cutting Costs, Not Corners: Managing Cattle in Tough Times. The take home message is to not just spend less, but instead develop a well conceived cost cutting plan for your operation. Profitability in a deflated market is a sizable challenge to overcome, but there are options worth considering as you work through this challenge.

For ideas on making the most of your investment in hay production, check out this article, previously published in Panhandle Ag e-news: Improving the Efficiency of Your Hay Production

Source:ufl.edu