By Mike Staton

Soybean harvest losses typically range from 1 to 2 bushels per acre under good harvest conditions representing approximately 2-4% of total potential yield, according to Joe Gleim et al. and Gary Huitink. Although this may seem insignificant, harvest losses can be much higher when soybean plants are short with low hanging pods, lodged, have green or tough stems, or contain brittle pods due to harvest delays. This article provides information about the causes of soybean harvest losses and practical recommendations for reducing them.

Total harvest losses come from three sources: pre-harvest losses, gathering losses and separating/cleaning losses. Gathering losses occur whenever loose soybeans, detached soybean pods or pods attached to uncut or cut stems are not picked up by the combine and left in the field.

Pre-harvest losses refer to all losses that occurred in the field prior to harvest. There are several causes of pre-harvest losses but the most common are hail damage after the plants have reached physiological maturity and harvest delays caused by a variety of factors.

Separating/cleaning losses happen inside the combine where the beans are threshed from the pods and all or most of the chaff (stems, threshed pods and leaves) is discharged from the back of the combine. Separating/cleaning losses typically occur when the amount of plant material entering the combine exceeds its separating and cleaning capacity. Common causes are very high yields, excessive ground speeds, slug (uneven) feeding, and wide headers that are not properly matched to the capacity of the combine. Worn or damaged separating parts and improper combine adjustments can also cause separating and cleaning losses. Most combines are equipped with grain loss monitoring technology designed to detect changes in separating and cleaning losses.

Gathering losses account for nearly 90% of total losses, according to Gary Huitink. Because gathering losses are responsible for most of the total harvest losses, most of the recommendations provided in this article are focused on reducing gathering losses.

Crop conditions that increase gathering losses

Shattering

Shatter losses occur when harvest operations cause the pods to open and loose beans fall directly on the ground or on the grain table but fail to enter the combine. Shawn Conley and Laura Lindsey identified drought conditions during the growing season and repeated wetting and drying cycles occurring after the beans initially dry to 13% moisture as frequent causes. Low moisture levels in the seed (less than 11%) at the time of harvest is also an indicator that shattering is likely to occur. Spider mite feeding has also been shown to make soybean pods more brittle and prone to shattering. Photo 1 shows volunteer soybean plants sprouted from unharvested beans.

Lodging

Lodging occurs when the plant stems cannot hold the plants upright and they lean or fall over. This can increase harvest losses and slow harvest operations. Abundant rainfall or irrigation water applications during the vegetative growth stages are the primary environmental conditions leading to lodging according to William Kranz and Jim Specht. These conditions produce taller plants that have longer internodes. Lodging causes harvest losses because the cutter bar rides over leaning plants leaving uncut plant parts in the field. The following management practices can reduce the potential for lodging to occur:

- Planting varieties resistant to lodging (Photo 2).

- Planting at low to moderate seeding rates.

- Maintaining adequate potassium soil test levels.

- Avoiding applications of nitrogen fertilizer or livestock manure prior to planting soybeans.

Green stem syndrome

Green stem syndrome (Photo 3) is a condition that causes the plant stems to stay green even after the pods and seeds are fully mature and have dried to acceptable moisture levels for harvest. Although certain viruses and foliar fungicide applications have been associated with green stem syndrome, the most frequent cause is physiological according to David Holshouser. Dry conditions existing during pod set and early seed development followed by adequate rainfall favor the development of green stems. The plant leaves produce more carbohydrates through photosynthesis than the reduced number of developing seeds can utilize, causing them to remain in the stem.

Farmers don’t like harvesting plants with green stems because they significantly slow harvest operations, increase fuel costs and can cause the combine to become clogged with green plant material. Delaying harvest causes the pods to undergo repeated wetting and drying cycles, making them brittle and prone to shattering.

Short plants with low pods

Mark Licht identified extended periods of cool, wet and cloudy weather following soybean emergence as a leading cause of short plants. Drought conditions occurring during the growing season and significant planting delays also create short plants. Short plants increase harvest losses in two ways. The first is the pods are closer to the ground, so the cutter bar cuts the stem off above them, and the pods remain on the stubble or pods are cut directly by the cutter bar (Photo 4). The second reason is the short main stems and branches are more difficult to gather into the combine after being cut.

Measuring gathering losses

Because gathering losses account for up to 90% of the total harvest losses, the following information pertains to isolating and measuring only the gathering losses.

Walk into the standing crop and estimate the number of loose beans and beans in pods per 1 foot2 found on the ground. In most cases, this will be negligible. The next step is to begin harvesting the field and stop the combine in a representative area and raise the header. Back the combine up approximately 30 feet. The area in front of the combine that is free of chaff is where the gathering losses can be measured.

To measure harvest losses, count all loose beans and all beans contained in pods on the ground or attached to the uncut stubble within 1 foot2. To do this, make a square that has an inside area measuring 1 foot2. Polyvinyl chloride (PVC) pipe with a diameter of 1 inch works well as a building material. To ensure a representative sample, take counts from at least 10 different spots across the entire width of the header (Photo 5). Add these up and divide by the total number of individual counts made to determine the average number of beans per 1 foot2. The count expressed as beans per 1 foot2 can be easily converted to bushels per acre by dividing by four (four beans per 1 foot2 equals 1 bushel per acre). When dropping the square, avoid unrepresentative areas such as areas where the plants were impacted by sprayer tracks.

Under good harvest conditions, gathering losses near 1 bushel per acre requires no adjustments. However, if losses approach or exceed 2 bushels per acre, the operator should inspect the cutter bar, decrease ground speed or adjust reel speed and/or reel position. The following information will cover general recommendations for reducing soybean harvest losses under good conditions and specific recommendations for the challenging conditions identified and described earlier.

General recommendations for reducing soybean harvest losses

Harvest timing

Research conducted at the University of Wisconsin by Philbrook and Oplinger showed that harvest timing directly affects soybean harvest losses. Many producers wait until all the plants have lost all their leaves and the moisture level in the beans is at or below 13% before beginning harvest operations. They do this to avoid moisture shrink and drying charges at delivery. Whenever soybeans having moisture levels greater than 13% are delivered for sale, grain buyers apply a moisture shrink factor to subtract the unwanted water weight and assess a drying charge to the load. Moisture shrink factors and drying charges are not assessed on soybean loads having moisture levels of 13% or lower. However, seed moisture levels can drop quickly in a single day under good drying conditions, and it is not uncommon to harvest soybeans below 11% which increases the potential for shatter losses. Beginning harvest operations earlier in the season and earlier in the day when the beans are at 15% to 16% moisture is a profitable practice. Table 1 shows how harvest moisture affects net income at delivery using common shrink factors and drying charges.

Table 1. Effect of harvest moisture on soybean income.

*Assuming a soybean market price of $13.25 per bushel and common grain elevator shrink factors and drying charges.

Equipment maintenance

Inspection and maintenance of the cutter bar is essential to reducing soybean gathering losses by ensuring a crisp cutting action. This is always true, but it becomes significantly more important under challenging conditions. Make sure that all knife sections are intact, sharp, and tight and all guards are properly aligned. Check the hold-down clips to ensure they hold the knife to within 1/32 of an inch (thickness of a business card) of the guards. Adjust the wear plates to the point that they lightly touch the back of the knife. Individual knife sections are available in two widths – 1.5 inches and 3 inches. The narrow knife sections are thought to reduce harvest losses when pods are brittle and likely to shatter due to less shaking of the plants and to provide more even cutting at higher ground speeds, according to Tim Harrigan et al. and Gary Huitink.

Equipment selection

Air-assisted reels, also known as wind systems or air bars, refer to equipment added to the header to create a stream of air directed toward the rear of the cutter bar and just above it (Photo 6). The air stream helps to move loose beans, pods and short plants past the cutter bar and into the combine. This technology also helps reduce slug feeding, increasing combine separating and cleaning capacity.

There are two equipment technologies currently available for moving the cut plants across the header and into the feeder house—augers and conveyor belts. Augers are older technology and more common on headers up to 35 feet wide. They can feed the crop uniformly into the combine under most conditions when properly adjusted. However, when the plants are damp, which commonly occurs in the morning or when the dew sets in in the evening, the plants will build up at the far ends of the header and harvest operations will need to cease until the plants dry.

Draper headers utilize conveyor belts to move the cut plants into the combine. The main advantage of Draper headers is uniform feeding of plant material into the combine under a wide range of conditions. This maximizes the combine’s separating and cleaning capacity and enables producers to start harvesting sooner in the day and to harvest later in the day, increasing their harvest capacity per day. The addition of an air-assisted reel will reduce gathering losses on these headers.

Stones and uneven soil surfaces slow down harvest operations and can increase gathering losses. Stones are particularly troublesome as they can enter the combine causing down-time and expensive damage to the internal components. Some producers pull large land rollers across their soybean fields to level the soil and push large stones into the soil (Photo 7). According to DeJong-Hughes et al., this extra field operation significantly reduces down-time, damage to equipment and combine operator fatigue and allows faster ground speeds during harvest operations. Another option for reducing the potential for stones to enter the combine is to install a removable stone dam (1.5- to 3-inch-tall steel wall) on the back of the cutter bar.

Operator skill and combine adjustments

Joe Gleim and Gary Huitink found that a highly skilled operator has the greatest impact on minimizing harvest losses. Research has shown that combine adjustments are required every two to three hours to optimize harvest efficiency. The value of operator skill has also been demonstrated repeatedly at soybean harvest equipment field days.

Improper reel speed and reel position are responsible for more shatter losses than any other maladjustment according to Gary Huitink. A good rule of thumb is to operate the reel speed at 10-25% faster than the groundspeed when the crop is not lodged. The optimal speed is attained when the reel slightly contacts the plants and appears to be pulling the combine into the crop. Most newer combines are equipped with an automatic reel speed adjustment that adjusts the reel speed as ground speed changes.

Reel position is also an important adjustment. The height of the reel should be set so that the reel strikes the top third of the plants. Fore and aft position of the reel affects the uniformity of the crop feeding into the combine. A good starting point is to position the axis of the reel 6-12 inches in front of the cutter bar and to move the reel back if slug feeding occurs.

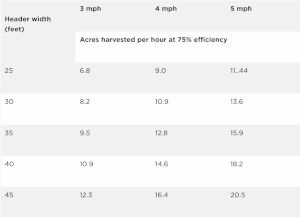

Matching combine ground speed to the field conditions will help reduce gathering losses. Under ideal conditions, ground speeds as high as 5 mph may be possible while slowing down to 2.5 mph may be necessary under more challenging conditions. Uneven, ragged stubble and loose pods on the ground are indicators that the ground speed is too fast. Producers tend to operate combines at higher forward speeds because they want to increase harvest capacity (i.e., area harvested per day). However, this can be a balancing act between maximizing harvest capacity and yield. Table 2 shows how ground speed affects harvest capacity.

Table 2. Effect of combine ground speed on soybean harvest capacity.

Specific recommendations for reducing harvest losses under challenging harvest conditions

Shattering

- Decrease your ground speed to 2.5 – 3 mph.

- Plant a range of soybean maturities that are adapted to the area to help prevent all fields from being ready to harvest at the same time.

- Begin harvesting when the beans in the earliest maturing field first reach 15% to 16% moisture.

- Complete harvest operations before the beans and pods undergo repeated wetting and drying cycles after they have reached 13% moisture.

- Avoid harvesting beans that are under 11% moisture when excessive shatter losses are occurring.

- Under hot and dry conditions, harvest in the morning and in the evening when the pods and beans have picked up some moisture and avoid the heat of the day if shatter losses are excessive.

- Reduce the speed of the reel in relation to the ground speed if the reel is flailing beans out of the pods. Beans hitting the combine’s windshield is an obvious sign that the reel speed needs to be reduced.

Lodging

- Decrease your ground speed to 2.5 – 3 mph.

- Position the cutter bar as close to the ground as possible.

- Angle the pickup fingers on the reel back slightly to pull the lodged plants more aggressively to the cutter bar. Reduce the angle of the fingers if the plants are riding over the top of the reel.

- Move the reel axle forward so that it is 9 – 12 inches ahead of the cutter bar.

- Contact the manufacturer for specific recommendations if using an air-assisted reel in lodged soybeans. Moving the reel forward to pick up lodged plants decreases the performance of air-assisted reels. Pivot the drop tubes above the crop if this option is available or remove the entire air manifold and drop tube assembly.

- Operate the reel as low as necessary to pick up lodged plants without causing them to ride over the top of the reel. Raise the reel if this happens.

- Install crop lifters on the cutter bar in conditions of severe lodging.

- When the plants are lodged in one direction, use crop lifters and travel at a 20- to 25-degree angle to the direction of lodging. Alternatively, harvest the lodged plants traveling opposite to direction they are leaning.

- Increase the reel speed relative to the ground speed. It may be challenging to maintain the correct ground and reel speed combination in lodged beans with brittle pods. When ground speed is too fast relative to reel speed, the cutter bar will ride over some plants. When the reel speed is too fast relative to ground speed, the reel may shatter the pods. The reel should run 10 to 25% faster than ground speed under ideal conditions. However, in lodged beans, increase the reel speed incrementally up to a maximum of 50% faster than the ground speed. If the reel is causing pods to shatter, decrease the reel speed to the point when the shattering stops. If the cutter bar rides over lodged plants, decrease your ground speed.

Green stems

- It is critical to continue harvesting soybeans having green stems even though it requires slower travel speeds and closer attention to cutter bar maintenance, reel speed and position, and threshing adjustments. Waiting for the stems to dry down will lead to large shatter losses.

- If shatter losses are excessive, consider combining earlier in the morning or later into the evening when the pods have regained some moisture and are less brittle. However, this may increase plugging problems.

- Reduce your ground speed to 2.5 to 3 mph if necessary. This will reduce shatter losses and plugging at the cutter bar by providing a crisp sideways cut.

- Harvest at a 20- to 25-degree angle to the rows. This will improve cutter bar performance and provide more even feeding of the crop into the threshing cylinder or rotor. This may be the single most beneficial practice.

- Draper headers should also reduce plugging problems when harvesting soybeans with green stems as they provide more uniform feeding into the threshing cylinder or rotor.

- If the cutter bar is plugging, inspect and repair all identified problems. Check that the speed of the knife is correct and that drive mechanisms such as belts are not slipping. Make sure that the knife is in proper register with the guards. Rotate the knife through one complete cycle and make sure the tips of the knife sections are centered on a guard at the beginning of a cycle and end up centered on a guard at the end of the cycle.

- Maintain the reel speed at 10-25% faster than the ground speed. Fore and aft reel position is important to reducing slug feeding. Generally, positioning the reel as close to the auger as possible promotes even feeding into the combine.

- Separating problems result from worn parts on the cylinder or rotor and improper cylinder or rotor clearance or speed settings. The separating equipment must be in good condition to handle soybeans with green/tough stems. Adjustments made to the cylinder/rotor clearance and speed is a balancing act between separating losses and seed damage and split beans. Make one adjustment at a time and inspect the clean grain tank to determine your progress toward minimizing separating losses and maximizing seed quality.

Short plants with low pods

- Position the cutter bar as close to the ground as possible. Check and adjust the skid shoes on the bottom of the header to lower the cutter bar. You may need to increase the angle of the header to lower the front of the cutter bar (3 degrees is a good starting point). This is a balancing act, as too much of an angle may increase the potential to pick up soil and stones leading to more broken guards and knife sections and cause cut plants and loose beans to build up on the cutter bar. Too flat of an angle may leave unharvested pods on the stubble due to a higher cutting height.

- Purchase an air-assisted reel, wind system or an air bar as the air stream produced by this equipment effectively moves short plants and loose beans and pods to the auger or belt. Follow the manufacturers recommendations for positioning the outlets on the drop tubes to maximize performance.

- Remove the stone guard on the cutter bar if it is preventing short plants, loose beans and pods from moving to the auger or belt and you do not have an air-assisted reel.

- Harvest on a slight angle (15-20 degrees) in fields planted in 15- or 30-inch rows. This will usually help the short plants feed into the combine more uniformly.

- The position of the reel will be critical to reducing gathering losses when harvesting short plants. With auger headers, positioning the reel as close to the auger as possible provides the most uniform feeding under most conditions. However, you may need to experiment with fore and aft reel position with very short plants. Lowering the reel is recommended when plants are short to prevent the plants and beans from building up on the cutter bar. The tips of the reel fingers should be about 5/8 on an inch above the top of the guards or the header floor.

- Set the speed of the reel about 10-25% faster than the ground speed and adjust as necessary to improve feeding.

- Set the speed of the belts on draper headers fast enough to assure plant material isn’t building up on the cutter bar.

- Experiment with your ground speed to find the sweet spot where the cut plants are feeding well into the feeder house and the stubble is cut cleanly and uniformly.

- Reduce shatter losses by harvesting in the morning or evening when relative humidity is higher.

Source : msu.edu