By Ben Beckman

The past few months, we’ve been focusing quite a bit on the issues that can arise when hay gets a bit too wet: combustion, mold, and Maillard reactions. One often overlooked issue that can arise from wet hay is just the moisture itself.

Whenever we provide part of our animal’s daily feed, whether spreading hay on the ground or a ration in a bunk, cattle are trusting that we as producers are providing for all their energy and protein needs. We do this by running feed samples through lab analysis to determine nutrient value as a percent of the feedstuff which can then be converted into an amount of the nutrient on a weight basis (i.e. pound of protein per however many pounds of feedstuff).

When you get your feed analysis back and it says that the crude protein content of the alfalfa sample you sent in is 20%, that means that 20% by weight is protein. When we are developing rations, we want to be able to compare different feeds equally. We do this all on a 100% dry matter basis, meaning all the water content of the feed has been removed. Alfalfa that is 20% crude protein on a dry matter basis has the same amount of protein in it as an equal weight of 20% crude protein range cubes.

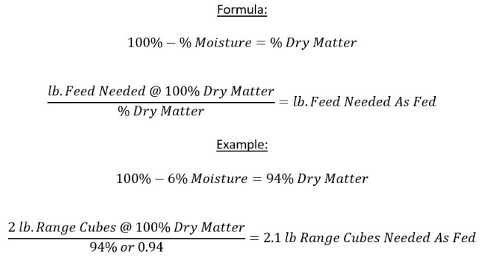

The catch comes when we get back to the real world and start to feed. For some products, like range cubes, we are almost at a 100% dry matter basis anyway. A typical range cube may run anywhere from 6-12% moisture, so adjusting for this additional weight here is small. If our plan calls for 2 lb. of range cubes on a dry matter basis to meet requirements and our cubes are 6% moisture, we only need to adjust slightly to 2.1 lb.

Other feedstuffs like hay, silage, or distillers have much higher moisture contents that we need to account for. If we were planning on feeding 2 lb. on a dry matter basis of our 20% crude protein alfalfa per head and the bales are sitting outside uncovered with a moisture content of 20%, a small adjustment won’t cut it. Just feeding 2 lb. of hay from the bale per animal won’t be enough to meet requirements with all that extra water weight. We have to increase our feed by 20%, so that each cow actually gets 2.5 lb. of as fed hay.

Making this adjustment is even more critical from an animal energy standpoint in the winter. Cold temperatures cause energy needs to increase from normal baseline maintenance in order to generate more heat. If we aren’t taking feed moisture in to consideration when feeding and are already not providing enough energy for animal maintenance, cold weather demands can send us into a tailspin very quickly.

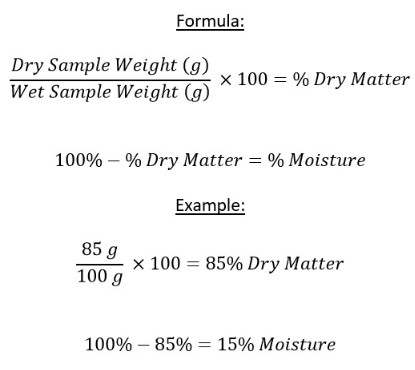

If you want to find the moisture content of your feedstuff without sending it to a lab for analysis, you can do some at home testing. Take a quart sized sample and get a weight in grams (just the sample, not the bowl holding it) and then spread it out in a dehydrator or you can use a microwave oven for quicker turn around. The goal for both of these is to dry out the sample, not burn or char it. If you see smoke, turn your temperature down. In the microwave, put a glass of water in the back corner to help prevent burning and run on 50% power for approximately 2 minutes starting out. Higher moisture samples, like silage, can take longer (up to 4 minutes), but as the sample dries, decrease the microwave time.

After the first microwaving or 30 minutes in the dehydrator, weigh the sample again. Keep microwaving or drying in the dehydrator and weighing at regular intervals until there is less than 2 grams difference between the current weight and the one taken just prior. To calculate the moisture content, divide the last weight (dry sample) by the first weight (wet sample), multiply by 100, and then subtract that answer (the dry matter content) from 100. For example, we weighed out 100 g of hay initially and ended up with 85 g of dried feed. This gives us a dry matter content of 85%, which when we subtract from 100 gives us a moisture content of 15%.

Whether providing some additional roughage to cattle on winter pasture or developing a full ration, having an accurate idea of the moisture content of our feedstuffs and how to adjust our feeding plans accordingly is important. It can be the difference between a cow that comes out of winter ready to breed back and one that ends up open in the fall.

Source : unl.edu