By James Morris, Will Hamman.et.al

The variability of the 2019 cropping year is continuing into harvest. With a broad range of planting dates this spring, many soybean producers will be faced with variable harvest conditions. Additionally, the hot and dry conditions this late summer into early fall has sped up the senescence and dry down of many soybean fields. While seed quality is currently very good, a few weeks of wet weather can degrade quality quickly. Be sure you are ready when the soybeans are.

When harvesting soybeans, harvest loss can be a real concern. The ideal time to harvest soybeans is when the soybean seed reaches 12-15% moisture. This will allow for optimal threshing and reduced harvest loss. Harvest loss can be very simply calculated by getting out of the combine and counting the soybean seeds on the ground. By randomly selecting a 1-foot by 1-foot area in a harvested part of the field, a producer can estimate harvest loss. Counting 4 soybean seeds per square foot is equal to 1 bushel/acre of loss. Due to the mechanical nature of a combine it is nearly impossible to gather every soybean seed in the field. An acceptable level of loss is 3% of yield or less, which is equivalent to 1-2 bushels/acre. If harvest conditions and combine adjustments are not optimal, harvest loss can reach 10% of yield and that can become very costly to the producer.

It is important for the combine operator to be checking harvest loss as well has the quality of the grain in the combine grain tank. Harvest loss can occur in three areas: 1) pre-harvest, 2) header and 3) combine. One should check these three areas within different locations in a field. Checking behind the combine represents total harvest loss, but one must check pre-harvest loss before combining an area, as well as just behind the header after harvested (header loss). Combine loss equals the total harvest loss minus the pre-harvest loss and header loss. Checking all three areas determines if and what combine settings must be adjusted, especially header loss.

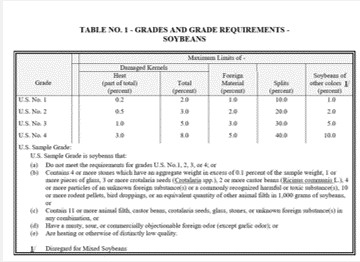

It is recommended to review the owner’s manual and/or consult your local combine dealer for help on proper combine settings specific to the crop and harvest conditions. Fine tuning adjustments from these settings will help optimize the effectiveness of the combine. Adjustments should be based on harvest conditions and grain samples from the tank, looking for cracked or damaged soybeans seeds as well as the amount of pod material or unthreshed pods in the sample, see Table 1 below for acceptable levels.

80% of harvest loss occurs at contact with the header.

- The following are a few tips to help reduce or minimize harvest loss:

- A floating, flexible cutterbar and automatic header height control can improve the ability to maintain the header low and level to the ground during harvest.

- Keep the cutter bar as low as possible for short soybeans and those that are dry. This point is important in areas with low plant populations and where more pods are on the lower portion of the plant, nearest the ground.

- Take time and slow the combine down. Slowing up 0.5 to 1.0 mph in areas where harvest loss might be risky.

- Shorter soybeans require smaller clearances between the reel, cutter bar, auger and the feed conveyor chain, to ensure stems are feeding through the platform and into the feeder house.

- Check knives, guards, ledger plates and wear plates, and keep spares handy.

- Ensure the sickle is sharp. Dull sickles tend to push stems over rather than cut them cleanly.

- Make sure to properly adjust guards and header to proper engagement angle as outlined in the operator’s manual.

- Check that stems are being cleanly cut across the header. If not, check for dull blades, improperly set header angle, other incorrect header settings, or reduce your ground speed.

- Keep an eye on reel speed and adjust to match soybean conditions and ground speed within the field. The rule of thumb is to keep reel speed ~25% faster than ground speed.

- Make sure the feeder house relative to the header is at the proper adjustment to keep material feeding as efficient as possible.

- Importantly, make sure chains and bearings are properly lubricated and serviced on their stated time intervals. Belts should be tight and checked routinely.

Another risk of harvest this fall is harvesting soybeans that were killed by a frost before reaching full maturity or natural senescence. If this occurs, producers can expect a higher than normal moisture at harvest. This may require combine settings to be adjusted to minimize harvest losses. Reducing the concave clearance as well as increasing rotor or cylinder speed for more aggressive threshing may be needed for wet, tough soybeans.

Soybeans are recommended to be harvested between 12-15% moisture for optimum weight and minimal field loss. When soybeans are at 18% moisture or above, they can easily be crushed, so it’s important to handle them with care to avoid any further losses. Soybeans that have not reached complete physiological maturity can cause issues as increased amounts of pods can enter the dryer. If beans are not properly cleaned before entering the bin, the excess pods and weed seed can result in decreased air flow and circulation and lead to increased insect population and mold growth. This can also increase the risk of a fire and the high oil content of soybeans makes a fire of this type tough to extinguish. Clean out the dryer frequently and keep a close watch when you suspect debris is entering the dryer. In cases like last year, if soybeans are severely damaged while still in the field, it is best to market them as soon as possible.

We may find ourselves having to dry some of our later planted stands. Due to the late harvest last year, this was a struggle for us and many others. Regardless of how much fuel was burned, we couldn’t get the moisture to drop. Ken Hellevang, an Agricultural Engineer for North Dakota State University Extension states that this happens due to “the moisture holding capacity of air being reduced at lower air temperatures. As average air temperatures approach 35°F, natural air drying becomes inefficient and not economical. Adding heat would cause the beans on the bottom of the bin to be dried to a lower moisture content and it would increase drying speed only slightly. Cool the soybeans to between 20°F and 30°F for winter storage and complete drying in the spring. Hellevang recommends starting drying in the spring when outdoor temperatures are averaging about 40°F.”

It is also important to ensure good ventilation when drying during cold temperatures. Check vents and exhausts for ice or frost to avoid damage to the roof. Leave the access door open to relive pressure when operating the fan at temperatures near or below freezing. Over drying can also be an issue. It’s important to not heat beans over 120 degrees Fahrenheit as high temperatures can cause damage to seed coats and lead to increased risk of the soybeans splitting. Hellevang also mentions that one study found temperatures of 130 degrees Fahrenheit caused 50-90% of seed coats to be cracked, increasing the amount of split beans to 20-70%. Table 1. outlines the grades and requirements for soybeans. If soybeans beans are already molded or discolored, over heating would only add more problems to the situation. As Table 1 shows, the limit of split beans is 10% for US No. 1 soybeans and 20% for US No.2 soybeans. Most molds and discolorations will grade as total damage and as shown below, only 2% is tolerated for US No. 1 soybeans and 3% for US No. 2 soybeans.

Harvested has already started for many producers across the state but it seems that several of us still have a few fields that were planted later than normal. As we begin to lose time for in-field drying, bin drying may be our next option. Bin drying is possible but must be done with care for our own safety and for grain quality. For storage, a normal soybean crop should be dried to 13% for a 6-month storage period, and 12% for 12 months of storage. For lower quality soybeans, experts suggest drying grain 1 or 2 points below that required for a normal crop. More information can be found at the following links.

Source : osu.edu