By Ben Phillips, Michigan State University Extension

Weeds, nitrogen and equipment calibration are factors to consider when cover cropping and using conservation tillage in a butternut squash system.

This article was originally published in the Vine Crop Session Proceedings of the Great Lakes EXPO, Dec. 9, 2015. You can also watch a webinar of the following findings being presented starting at 28:50.

A Specialty Crop Block Grant from the Michigan Department of Agriculture and Rural Development funded a one-year cover cropping trial in butternut squash. The trial was planted at the Forgotten Harvest Ore Creek Farm (9153 Major Rd, Fenton, MI 438430). The objective was to determine how water and yields were conserved by six cropping systems: bare ground disked rye without irrigation, no-tilled rye without irrigation, no-tilled rye with irrigation, strip-tilled rye without irrigation, strip-tilled rye with irrigation and plastic beds with irrigation. The bare ground and plastic treatments served as negative and positive controls, respectively, as the grower-cooperator was most familiar with these growing methods. All irrigation was supplied through pressure compensating drip lines at a rate of 0.25 global precipitation measurement (gpm) per 100 feet.

Overview of the trial plots.

On Oct. 15, 2014, cereal rye was drilled into the two-acre experimental area at a rate of about 73 pounds per acre. Three replicated plots (150 feet x 150 feet) of all six subplots (150 feet x 25 feet) were measured on Nov. 26. A 12-foot drive lane separated each replicated plot, and a 12-foot drive lane for a sprayer bisected all plots into two 69-feet sections. The soil type was a Miami loam with a 6-11 percent grade. Pre-plant fertilizer was broadcast at a rate of 80 pounds nitrogen (N), 20 pounds phosphorus (P) and 105 pounds potassium (K).

Between May 20 and June 25, 2015, each subplot treatment was created. The entire area was sprayed with glyphosate (1 quart per acre) before all of the rye was rolled perpendicular to the direction it was planted with a roller-crimper (I & J Manufacturing, 5302 Amish Rd, Gap, PA 17527). A custom-made, one-row strip-tiller was borrowed for the strip-tilled subplots, bare ground subplots were created with two passes of a chisel plow and 10 feet disc implement, and a one-row plastic and drip tape layer was used to create beds in the plastic subplots (watch a video of the custom-made, one-row strip tiller in action). Dual Magnum was used as a pre-emergent herbicide (1.33 pints per acre), and a commercial push-style deck mower was rented to cut back between-row weeds on Aug. 5. Drip tape was later added to one of the two no-till and strip-till subplots in replicate plots.

On July 1 and 2, all butternut squash (Betternut cultivar) were hand-planted with tube seeders (Stand ‘N Plant, 95 Rose Rd, Saltsburg, PA 15681). Plastic subplots contained four bedded rows 6.25 feet apart seeded with two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 feet apart seeded with in-row spacing of 24 inches (375 plants per subplot). Seeds were coated in the Farmore F1400 chemical treatment consisting of thiamethoxam, mefenoxam, fludioxonil and azoxystrobin. The only other pesticide applied was Kocide 3000 (copper hydroxide) on Aug. 18 at a rate of 1.25 pounds per acre.

On June 25, all moisture-monitoring tubes were installed to a depth of 15.75 inches, and weekly moisture monitoring with the Sentek Diviner 2000 (Sentek Sensor Technologies, 77 Magill Road, Stepney SA 5069, Australia) occurred between July 8 and Oct. 2. By Aug. 11, all irrigation tubing was installed in irrigated plots. Rainfall accumulation was logged by the Runyan Lake Road weather station 3.6 miles northeast of the plot.

On Oct. 8 (day 100), harvest transects were measured 20 feet on either side of the center drive lane. Weed pressure was assessed in each treatment subplot on a 1-9 scale (1 = no weeds visible and 9 = no crop plants visible), the number of plants were counted and fruit were tallied as “good and clean,” “good and dirty” and “cull.” All good fruit were combined and weighed.

Pollination was provided by four bumble bee quads from Koppert Biological Supply (1502 Old US-23, Howell, MI 48843), and three nearby honey bee hives.

Moisture monitoring

The Sentek Diviner 2000 measures moisture within 10 centimeters surrounding the monitoring tube, and takes samples every 10 centimeters of depth. Though the Sentek moisture units are not in cubic inches, we were able to generate relative comparisons of “volumetric moisture content” at different depths between treatments. For analysis, moisture readings for all depths were integrated within each treatment subplot, creating one average volumetric moisture content reading for each date.

What establishment, yield and quality performance did we expect?

- Our positive control, plastic with drip irrigation, would establish faster and produce the cleanest fruit.

- No-till yields would be the slowest to establish yet cleanest because of the mat of cereal rye blocking sunlight and heat from the seedbed.

- Similar yields between plastic subplots and conservation tillage subplots with equal plant populations.

- Similar yields between strip-till plots and bare ground plots because of the tilled soil more exposed to the thermal energy of the sun.

- Higher yields in irrigated subplots.

What moisture dynamics did we expect?

- No-till and plastic subplots would maintain higher soil moisture levels within the top 40 centimeters of soil over time.

- Irrigated subplots would maintain higher soil moisture levels within the top 40 centimeters of soil over time.

Results

Establishment

Soil hardness, row markings and walkability were key factors in ranking the ease of hand seeding. Plastic beds required an additional step of running a dibbler to place holes in the plastic before seeding. Once holes were established, it was problematic to walk on the plastic beds to seed. No-till and bare ground subplots were hard to maintain straight rows and required an additional step of marking with string. No-till subplots had noticeably harder soil that challenged the seeding tools. Rankings of the ease to plant are in Table 1.

Yield

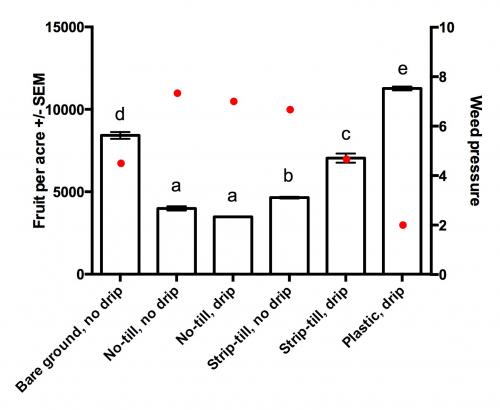

Weed pressure (broadleaf complex of lambsquarters, velvetleaf, nightshade, pigweed, and jimson weed) was high across the research area, but it is difficult to determine whether weeds where the cause or effect of the number of squash plants per acre (Table 1). Weed pressure was highest in no-till treatments, which took at least five full days longer to emerge than plastic and bare ground subplots. Irrigated strip-tilled subplots had lower weed pressure than unirrigated subplots, and had similar pressure to bare ground subplots. Weed pressure in plastic subplots was the lowest. Bare ground plots and plastic plots maintained the highest number of plants per acre, and were the first to emerge.

The hard surface of the no-till treatments made hand seeding more difficult and could have caused more skips and gaps in emergence and resulted in fewer plants per acre and weed proliferation. However, three factors may have allowed heavier broadleaf weed pressure overall:

- The seed drill was not calibrated, and actually seeded two-thirds of the rate required for the recommended population of 110 pounds per acre of rye.

- The sprayer booms appeared to deliver inconsistent active ingredients to the far ends of the booms.

- We forewent the typical addition of Command 3ME to the pre-emergent herbicide tank-mix, which has good efficacy on some of the prevalent broadleaf weeds in the plots, and delayed out pre-emergent application of Dual by a week after a second post-emergent burndown with Roundup. Therefore, weed competition was a real effect on crop stand.

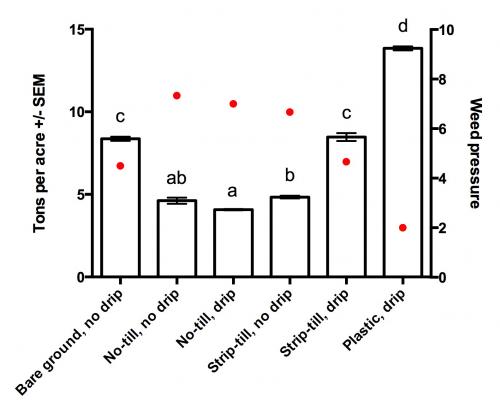

The number of fruit and tonnage produced in each treatment was also varied (Figure 1). No-till plots had the least amount of fruit, and there was no significant difference between irrigated and unirrigated no-till treatments. The irrigated strip-till treatment produced significantly more fruit per plant than the unirrigated treatment, and both strip-till treatments produced more fruit than no-till treatments. The bare ground treatment produced significantly more fruit per acre than any conservation tillage treatment, and the plastic treatment significantly out-produced all other treatments. The fruit from the irrigated strip-till treatments were heavier than all other treatments. As a result, the bare ground treatment did not produce a significantly higher tonnage of fruit than the irrigated strip-tilled treatment when weight was considered.

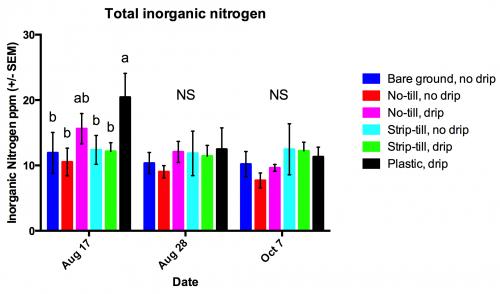

In general, yields were below the normal 12-22 tons per acre range to be expected in a winter squash crop in most subplots (Table 1). Plasticulture subplots attained 13 tons per acre on average, which was still a relatively low yield. We suspect that nitrogen availability played a role in low yields overall. After 45 days, all plots had less than 25 parts per million (ppm) of inorganic nitrogen available to the root zone, and could have benefitted from a split N application. However, plasticulture plots held on to the most nitrogen for longer. We suspect the plastic increased N mineralization by warming the soil, and reduced leaching from rain.

Quality

Despite lower yields, a higher percentage of fruit harvested from no-till subplots were free of dirt (Table 1). Plastic rows also had cleaner fruit. Bare ground subplots had the second lowest percentage of clean fruit. Interestingly, the treatment with the lowest percentage of clean fruit was the unirrigated strip-till subplots. This could have been a result of poor rye stand and bare soil in strip-tilled plots.

Moisture dynamics

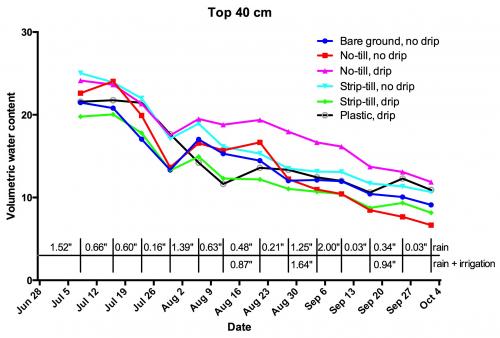

Unirrigated bare ground, no-tilled and strip-tilled subplots received a total of 9.74 inches of rain throughout the study, averaging 0.65 inches per week. Irrigated no-till, strip-till and plastic subplots were irrigated three times on top of that. On Aug. 12 and Sept. 3 the irrigation ran for 4 hours, applying the equivalent of 0.16 inches of rain to the plastic treatment and 0.2 inches to other irrigated treatments. On Sept. 23 the irrigation ran for 6 hours, applying the equivalent of 0.23 inches of rain to the plastic treatment and 0.29 inches to other irrigated treatments. In total, irrigated plastic subplots received 15.18 inches of water throughout the study, averaging 1.01 inches per week. Irrigated no-till and strip-till subplots received 15.82 inches, averaging 1.06 inches per week

Analysis comparing each treatment was performed separately for each week of sampling to determine how each treatment handled soil moisture through the season. There were no significant differences in moisture concentration between cover treatments or irrigation treatments at any point in time through the sampling period in the top combined 40 centimeters, even before and after rain and irrigation events.

However, interesting patterns can be seen in the data (Figure 3). Between July 26 and Aug. 2, the weather station logged 1.33 inches of rain that is reflected in all subplots except the plastic treatment, which was protected from this rain. When the irrigation ran on Aug. 12, the moisture levels in the plastic subplots and irrigated no-till subplots also showed an increased water concentration, but the 0.48 inches of rain logged that week seemed to affect the unirrigated no-till subplots disproportionately. From the beginning of August through the end of the study period, the higher moisture retention of irrigated no-till subplots could have been an indication of low squash population, as healthy squash plants remove a lot of water. From Aug. 23 through Sept. 20, neither rainfall nor irrigation events were effective at raising the moisture concentration of the soil. Because all treatments failed to respond, we suspect flower and fruit set demand of squash plants and weeds was responsible for efficiently removing excess water inputs at this point in time. By the time of the last rain event on Sept. 18 and the irrigation event on Sept. 23, squash plants were dying back in all subplots and water inputs were more easily measured in irrigated strip-till and plastic subplots. Also at this point in the season, weed proliferation was at its maximum level in no-till subplots, and it is likely these weeds intercepted any rain or irrigation inputs during this period.

Special thanks to Mike Yancho Jr. and Anne Ginn of Forgotten Harvest, and Dan Brainard and Lab of Michigan State University.

Table 1. Measured characteristics of six cover crop, tillage, and irrigation treatments used to grow butternut squash at the Forgotten Harvest Ore Creek Farm, Fenton, MI. |

|---|

Treatment | Ease of seeding1 | Weed pressure2 | % Clean fruit | Fruit/plant | Plants/acre | Fruit/acre | Tons/acre |

|---|

Bare ground, no drip | 3 | 4.50 | 22.41 | 2.21 | 3775.25 | 8421.72 | 8.37 |

No-till, no drip | 4 | 7.33 | 30.91 | 1.14 | 3412.25 | 3993.06 | 4.62 |

No-till, drip | 4 | 7.00 | 35.42 | 1.30 | 2758.84 | 3484.85 | 4.07 |

Strip-till, no drip | 1 | 6.67 | 12.50 | 1.30 | 3702.65 | 4646.46 | 4.84 |

Strip-till, drip | 1 | 4.67 | 27.84 | 1.96 | 3630.05 | 7042.30 | 8.47 |

Plastic, drip | 2 | 2.00 | 30.41 | 2.66 | 4239.90 | 11267.68 | 13.84 |

Plastic subplots contained four bedded rows 6.25 ft apart seeded in two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 feet apart seeded with in row spacing of 24 inches (375 plants per subplot). All subplots were harvested at 100 days after planting.¹Ease of planting was ranked; 1=easiest, and 4=hardest. ²Weed pressure was assessed on a 1-9 scale in each subplot (1 = no weeds visible, and 9 = no crop plants visible).

Figure 1. Fruit per acre (left axis; bars), and weed pressure (right axis; red dots) measured in six cover crop, tillage, and irrigation treatments used to grow butternut squash at the Forgotten Harvest Ore Creek Farm, Fenton, MI. Plastic subplots contained four bedded rows 6.25 ft apart seeded in two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 ft apart seeded with in row spacing of 24 inches (375 plants per subplot). All subplots were harvested at 100 days after planting. Bars with the same letters do not differ significantly at P=.05 based on Tukey’s test.

Figure 2. Tons per acre (left axis; bars), and weed pressure (right axis; red dots) measured in six cover crop, tillage, and irrigation treatments used to grow butternut squash at the Forgotten Harvest Ore Creek Farm, Fenton, MI. Plastic subplots contained four bedded rows 6.25 ft apart seeded in two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 ft apart seeded with in row spacing of 24 inches (375 plants per subplot). All subplots were harvested at 100 days after planting. Bars with the same letters do not differ significantly at P=.05 based on Tukey’s test.

Figure 3. Volumetric moisture content in the top 40 cm of soil over time measured in six cover crop, tillage, and irrigation treatments used to grow butternut squash at the Forgotten Harvest Ore Creek Farm, Fenton, MI. Rainfall and irrigation accumulation in inches is shown for each week between samples. Plastic subplots contained four bedded rows 6.25 ft apart seeded in two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 ft apart seeded with in row spacing of 24 inches (375 plants per subplot). All subplots were harvested at 100 days after planting.

Figure 4. Parts per million of inorganic nitrogen measured in six cover crop, tillage, and irrigation treatments used to grow butternut squash at the Forgotten Harvest Ore Creek Farm, Fenton, MI. Rainfall and irrigation accumulation in inches is shown for each week between samples. Plastic subplots contained four bedded rows 6.25 ft apart seeded in two staggered rows with an in row spacing of 39 inches (379 plants per plastic subplot). All other treatment subplots contained five flat rows 5 ft apart seeded with in row spacing of 24 inches (375 plants per subplot). All subplots were harvested at 100 days after planting. Bars with the same letters, or NS, do not differ significantly.