As farmers prepare for crop planting, its important to calibrate dry fertilizer spreaders to make sure you are getting a good pattern in the field. Most newer spreaders calculate the rate per acre for you, in other words, you may know how many pounds of material you are putting out per acre, but you should also check to make sure the spreader applies evenly. You want an even spread with no heavy or light streaks.

UGA Calibration of Bulk Dry Fertilizer Applicators

The following are just a few key points from this publication.

Spreader Calibration Kit

Calibration checks for solid fertilizer equipment should show the type of spread pattern (including the degree of uniformity obtained across the swath), the effective swath width and the rate of application. Carry out these checks to determine any necessary adjustments to maintain or improve the characteristics of the applicator. One practical method of calibrating fertilizer and lime spreaders requires the following supplies:

- Nine to 15 collecting trays or pans with a grid baffle in the bottom of each (this prevents the material from bouncing out)

- Nine to 15 test tubes (use the same amount as for #1, above)

- Test tube rack

- Funnel

- 10-foot measuring tape

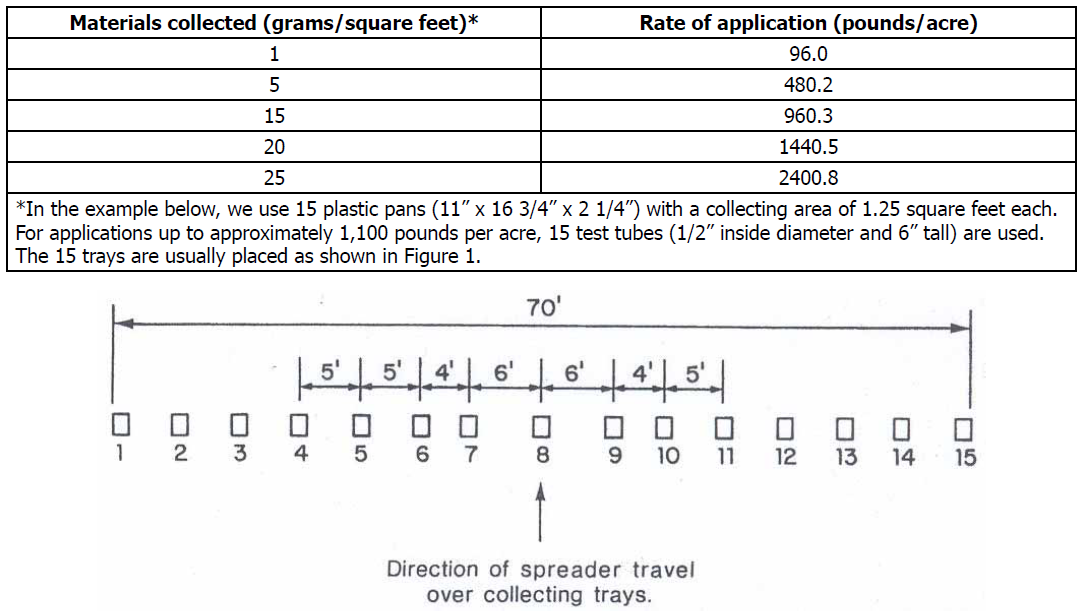

Make sure the sizes of the test tubes are in proportion to the rates of application being checked. All trays must be of identical size and shape. Trays should be shallow (2.5 to 4 inches deep) with a collecting area of 1.25 to 3 square feet each. The following table can be used to determine the rate of application from any size collecting tray:

A field layout of collecting trays showing extra clearance on each side of center trays for spreader wheels. All trays are placed at 5-foot intervals except for trays 7 and 9, which are placed 6 feet from the center tray (number 8). The collecting tray area should be 1.25 to 1.3 square feet with grid baffles in the trays to prevent fertilizer from bouncing out.

Source:ufl.edu